The Ultimate Guide to Electrical Connector: Types, Uses and Factors to Consider When Selecting A Suitable One

Electrical connectors are essential components of any electrical wiring system. This guide provides an overview of the electrical connector, the various types of electrical connectors available, their uses, and how to select a suitable electrical connector as well as the benefits of using the electrical connectors. With this information, you can make sure that your electrical wiring system is safe and secure.

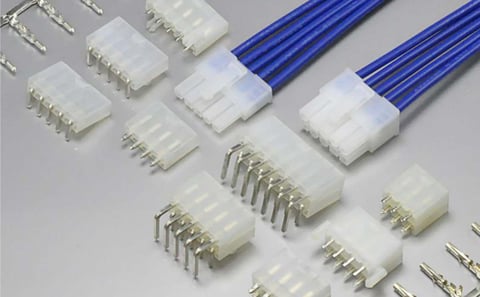

What is An Electrical Connector

An electrical connector is a device that helps in establishing an electrical connection between two or more components of an electric circuit, thus linking them together and forming a larger network. Electrical connectors are typically divided into two types, male and female. The male component (known as a plug) is designed to fit into the female component (known as a socket). Depending on the application, these connections can be removable, require tools for assembly/removal or serve as permanent electrical joints between two points.

The electrical connector is composed of a fixed end electrical connector, that is, a female contact (socket), and a free end electrical connector, that is, a male contact (plug). The socket is fixed on the electrical parts through its square (round) plate (welding is also used in some cases). The plug is generally connected to the cable, and the plug and socket are connected through the connecting nut. The electrical connector is composed of three basic units: shell, insulator and contact body.

- Shell

The electric connector shell refers to the shell, connecting nut and tail accessory of the plug and socket. The function of the housing is to protect the internal parts of the electrical connector such as the insulator and contact body (the general name of the pin and socket) from damage. The upper positioning keyway ensures the positioning of plug and socket. The connecting nut is used for the connection and separation of the plug base. The tail accessory is used to protect the terminal between the conductor and the contact body from damage and to fix the cable. The shell also has certain electromagnetic shielding effect.

The shell is generally made of aluminum alloy (machining, cold extrusion, die casting). Steel shell is mostly used for glass sealing and high temperature resistance electrical connectors.

- Insulator

It is composed of pin insulator, socket insulator, interface sealing body and wire sealing body. It is used to keep the pin and socket in the set position, and to make electrical insulation between each contact body and between each contact body and the shell. The sealing measures are obtained by adding insulator and interface sealing body and sealing body to improve the environmental resistance of electrical connectors.

In order to maintain high temperature resistance, low temperature and flame resistance, and ensure the stability and reliability of the geometric dimensions of the parts, most of the insulators are molded with thermosetting plastics. The interface sealing body and wire sealing body are molded with silicone rubber.

- Contact body

The contact body includes the male contact and the female contact, sometimes also known as the pin and socket. The connection mode is divided into welding type, crimping type, press-in type and winding type, etc., to realize the circuit connection.

The pin and socket are the key components of the electrical connector, which directly affect the reliability of the electrical connector. The contact pin and socket are mostly machined from elastic copper alloy material with good conductivity, and the surface is silver-plated and gold-plated to achieve the purpose of low contact resistance and corrosion prevention. The jacks generally include split slot jacks, wire spring jacks, crown spring jacks and punching jacks.

The structural features are: environment-resistant, bayonet type (fast) connection, multiple key positions (wrong insertion prevention), contact body and wire crimping connection (single piece is taken and sent for fault handling), and the shell equipped with shielding ring to achieve 360 ° electromagnetic interference shielding capability.

Different Types of Electrical Connectors Available

There are many different classification methods for electrical connectors. There are high-frequency electrical connectors and low-frequency electrical connectors according to frequency; There are circular electrical connectors and rectangular electrical connectors according to shape; Audio equipment electrical connector, power electrical connector, special purpose electrical connector, etc. There are many types of electrical connectors, which are usually classified according to their working frequency, electrical requirements and other characteristics.

Classified According to Different Working Frequency

- Low-frequency electrical connector

Generally, it refers to the electrical connector whose transmission signal frequency is less than 100MHz. This type of electrical connector has a large transmission current range, and its structure is mostly multi-wire (hundreds at most), including:

Cable electrical connector: This type of electrical connector is terminated by multi-stranded cable, shielded cable, solid wire, etc. The free end electrical connector and the free end cooperate with the electrical connector or fixed electrical connector.

Cabinet electrical connector: It consists of two pairs of fixed electrical connectors. They are respectively installed on the system frame and unit assembly, and connected and separated by the linear reciprocating motion of the unit assembly.

Electrical connectors of audio equipment: There are many kinds of electrical connectors, such as YS1 round electrical connector, concentric electrical connector, plug and socket used in audio equipment.

Electrical connectors for household appliances: These electrical connectors are mainly used in household appliances such as black-and-white televisions and color televisions, and also in devices with similar structures.

Electrical connectors for office equipment: These electrical connectors are mainly used for copiers, Chinese and English computer printers, microprocessors and other equipment.

Power connector of electrical and electronic equipment.

Environment-resistant electrical connector.

Special electrical connectors.

- High-frequency electrical connector

High-frequency electrical connector: It usually refers to the electrical connector used in circuits with operating frequency greater than 100MHz. The structure of such electrical connectors shall consider the leakage and reflection of high-frequency electric field. Because coaxial cable with coaxial structure is generally used for connection, it is also often called coaxial electrical connector.

- Hybrid high and low frequency electrical connector

Usually it refers to the electrical connector that contains both low-frequency and high-frequency contact pairs.

Classified According to Electrical Requirements

Electrical connectors can be divided into general electrical connectors, high-power electrical connectors, high-voltage electrical connectors, pulse electrical connectors, low-noise electrical connectors, anti-interference filter electrical connectors, phase-modulated electrical connectors, precision coaxial electrical connectors, etc. according to their electrical requirements.

Classified According to the Environmental Conditions

Electrical connectors can be divided into sealed electrical connectors, radiation-resistant electrical connectors, high-temperature electrical connectors, low-temperature electrical connectors, etc. according to their working environment conditions.

Classified According to Appearance Structure and Installation Method

Electrical connectors can be divided into circular electrical connectors, rectangular electrical connectors, straight electrical connectors, curved electrical connectors, and type 1 electrical connectors according to their appearance and structural characteristics. According to the installation method, it can be divided into cable electrical connector, panel electrical connector, through-wall electrical connector, etc.

Classified According to Special Structure

Electrical connectors with special structure include plug-in electrical connectors, rubber electrical connectors, rotary electrical connectors, split electrical connectors and optical fiber electrical connectors.

Factors to Consider When Selecting A Suitable Electrical Connector

There are a wide range of electrical connectors. In addition to the space and size limit of the connectors, three aspects should be considered when selecting them: electrical parameters, mechanical parameters, and natural environment parameters. Let's explain one by one.

- Electrical parameters

Consider the requirements of voltage, current, contact resistance, insulation resistance and withstand voltage.

- Mechanical parameters

Vibration and shock - select the corresponding connector according to the expected vibration and shock requirements.

Locking mode - locking modes include bayonet connection locking, thread connection locking, bayonet connection locking, push and pull connection locking, etc. To prevent connector separation caused by vibration and impact, safe and reliable connection mode must be selected.

Generally, the anti-vibration performance of threaded connection locking is the best. If necessary, the mechanical method of adding fuses can be used to improve the anti-vibration performance.

Positioning key - several positioning key structures can be selected at the same time to prevent the wrong insertion of adjacent similar connectors.

Installation method - determine whether the socket is installed before or after according to the equipment structure installation requirements.

Maintenance requirements - consider possible maintenance conditions to select appropriate termination methods, installation methods, etc.

- Natural environment parameters

Ambient temperature - The metal and insulating materials of the connector determine the working ambient temperature of the connector.

Humidity or water - For connectors used outside the equipment, the environmental conditions of humidity, water seepage and pollution shall be considered, and connectors with good sealing shall be selected.

Corrosive environment - according to the different corrosive environment, such as salt fog, mold and other environmental conditions, select the corresponding metal, plastic and coating connectors.

The Benefits of Using the Electrical Connectors

The use of electrical connectors for electrical circuits has the following advantages:

Improve production process

Connectors simplify the assembly process of electronic products. It also simplifies the batch production process;

Easy to maintain

If an electronic component fails, it can be replaced quickly when a connector is installed;

Easy to upgrade

With the progress of technology, the components can be updated when connectors are installed, and the old components can be replaced with new and more complete components;

Improve design flexibility

The use of connectors enables engineers to have greater flexibility in designing and integrating new products, and in composing systems with components.

I believe that you have a general understanding of electrical connectors and realized the benefits of using electrical connectors in electrical circuits. For more information, please click the official website link (https://wuhudinglian.v3.myfunpinpin.com/) here for the further consultation.